How To Choose the Right Commercial Embroidery Machine for Home Business

- Determine whether a flatbed or multi-needle machine would better suit your needs.

- Assess which machine aligns with the features you need.

- Check the necessity of attachments based on your target market.

- Research and identify the most suitable machine brand for your home embroidery business.

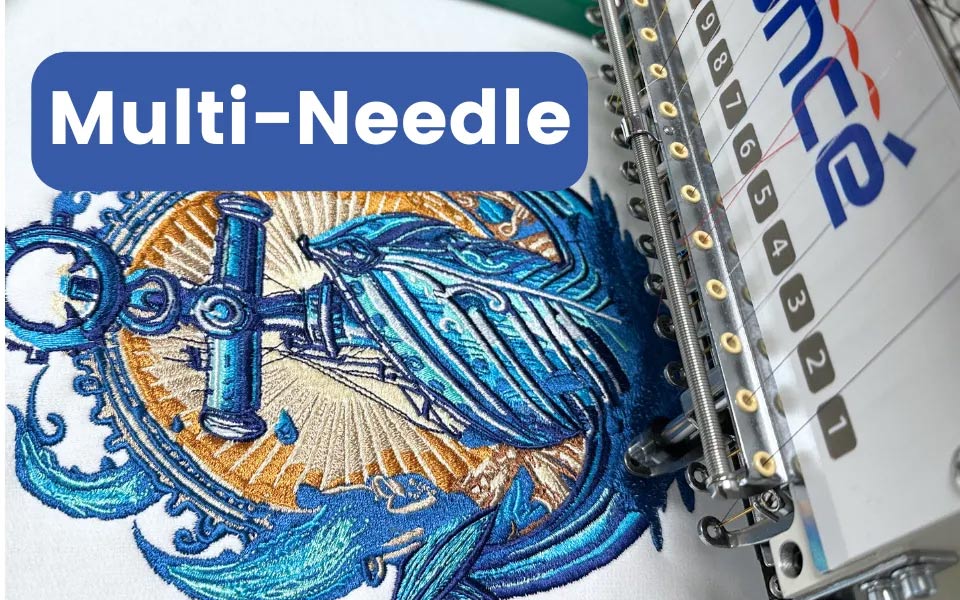

Choosing Between Multi-Needle and Flatbed Embroidery Machines

What type of commercial embroidery machine for home business do you need? If your goal is to expand your home embroidery business, you will want a multi-needle embroidery machine. Why?

- Flatbeds are not designed or engineered for commercial use.

Flatbed embroidery machines are not suitable for commercial purposes. The embroidery operates on a flat surface, so this makes it challenging to embroider tubular items such as shirts, socks, and caps. This limits your target market and profit potential.

- Multi-needle machines are faster and accommodate tubular items.

- Flatbed machines are slower and less efficient.

Flatbed machines experience decreased speed due to the rectangular hoop shape. This can cause issues with registration and embroidery quality. The hoop’s side that hooks into the machine frame drives the hoop back and forth. This slows down production time. The use of non-commercial grade motors contributes to slower production.

- Multi-needle machines offer the convenience of automatic thread color changes.

- Flatbeds can only run one color at a time.

Flatbed machines need you to stop the machine to change out the thread color. This interrupts the embroidery process, contradicting the goal of continuous production for optimal business revenue.

- Multi-needle machines allow a "set it and forget it" approach.

Optimizing Costs: Essentials Vs Bells and Whistles

If you are growing a home embroidery business, it’s essential to cut expenses. The right commercial embroidery machine for home business should align your required features.

High-end home brand machines offer features like positioning stickers and simulated embroidery images. These often come at a cost. These bells and whistles are not necessities for business owners. They can impact your bottom line.

Focus on practical aspects like attachments and the largest hoop size you will need. For instance, if you intend to embroider caps, focus on a machine with a cap attachment. If you plan to embroider larger items like sweaters or jacket backs, choose a machine with a max hoop size.

Aligning Embroidery Machine Attachments with Your Target Market

- Identify your business's target market.

- Determine the preferred items or garments your target market wishes to have customized.

- Assess the required hoop size and attachments necessary to fulfill orders.

The Benefits of Choosing a Trusted Commercial Embroidery Brand

Why should you buy from a reputable commercial embroidery brand?

- Reliability: Reputable brands have a history of producing reliable and high-quality embroidery machines. The equipment is usually known for its durability and consistent performance.

- Quality Output: Embroidery brands with a good reputation offer machines that produce high-quality embroidery. This is crucial for businesses aiming to deliver top-notch products to their customers. This will contribute to customer satisfaction and loyalty.

- Innovation and Technology: Established brands often invest in research and development as they stay ahead of technology and innovation. Partnering with a reputable brand ensures access to the latest features and advancements, helping your business stay competitive.

- Customer Support: Reputable brands provide excellent customer support services; this includes help with machine setup, troubleshooting, and addressing any issues that may arise during operation. Reliable customer support can save time and cut disruptions to your business.

- Warranty and Service Agreements: Reputable brands usually offer solid warranty options and service agreements. This provides a level of assurance that if the machine encounters problems, there are mechanisms in place for repairs or replacements. All this minimizes potential downtime for your business.

- Training and Resources: Many reputable brands offer training programs and resources, as well as documentation to help users make the most of their embroidery machines. This support is invaluable for businesses that may be new to commercial embroidery or are using advanced features.

What Commercial Embroidery Machine for Home Business Is Right for You?

Determining the ideal machine for your home business involves considering several factors. If your primary business focus is on embroidery, excluding sewing or quilting, you will need a multi-needle machine. Multi-needle machines enable embroidery on various garments.

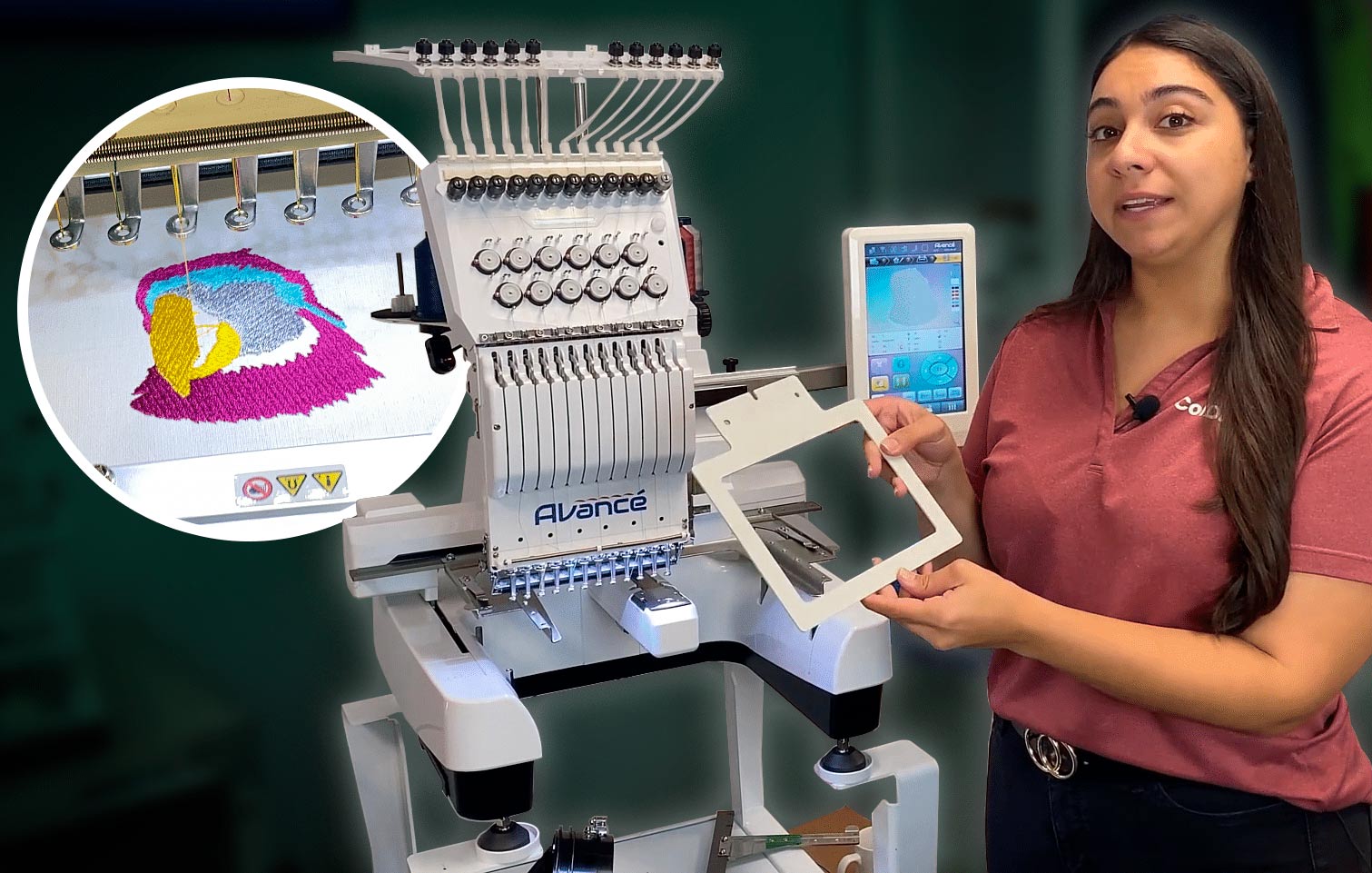

The ColDesi Avancé line of commercial embroidery machines have a well-established reputation. Backed by a history of assisting businesses like yours since 1978, ColDesi has been a dependable partner, helping businesses achieve their dreams of success.

Avancé commercial embroidery machines are renowned for their quality, precision, and reliability. They are equipped with a cap frame, a diverse selection of hoops, and various accessories, as well as essential supplies, a comprehensive five-year warranty, and more. ColDesi offers world-class training and support, seven days a week, for the lifetime of the machine.

Explore how Avancé Commercial Embroidery Machines can fulfill your embroidery needs.

Brainstorming ways to make money with commercial embroidery? Check out these 35 Embroidery Business Ideas.

Ready to Start or Expand Your Embroidery Business?

Chat with us below, call us at 877-793-3278 or click button and let us help you get your business growing.