Avancé 1501C

Multi-head Embroidery Machine Options

Buying multiple single-head embroidery machines makes better sense for today’s embroidery and customer apparel business

Investing in big multi-head embroidery machines – 6 head, 12 head and even larger – USED to make a lot of sense. That’s because each embroidery order was larger.

Big companies would order all the embroidery they needed for their employees at once and then stockpile extra shirts. High-quantity orders were the norm because the small and local businesses couldn’t easily afford the premium look of embroidery.

When you got an order for 800 or 1,000 Polo shirts with the same logo on each one, you almost HAD to have a big machine to make that work financially.

The cost per square foot on commercial space used to be a lot lower too. You had larger orders coming in. You were fulfilling them on big machines. And you needed a big space to hold it all.

But in TODAY’S custom apparel and embroidery market – things are different.

Today's Embroidery

But in TODAY’S custom apparel and embroidery market – things are different.

The embroidery shop of today is part of the “mass customization” trend that’s affected the custom t-shirt and promotional product business for so long.

Demand has changed

A typical embroidery order now is less than 36 pieces, and more often, under 12.

Since they’re used to ordering custom printed tees as one-offs or very small custom orders, they often expect to be able to do the same with embroidery.

So that typical order might be 2 positions – one logo + one name. It will be a dozen logo shirts and hats to match.

They will want each one to be different in some way that only THEY have imagined.

Today's Embroidery Business

Yesterday's Embroidery Business

The CUSTOMER DEMAND is different. The Business fulfilling that demand is different too!

The Modular Embroidery Machine Approach

Because ColDesi has deep ties into the embroidery business as well as the custom t-shirt printing, vinyl, t-shirt transfer, promotional product, and bling businesses, we have seen this trend across markets.

We’ve changed our approach to helping you be more successful in TODAY’S embroidery and custom apparel markets.

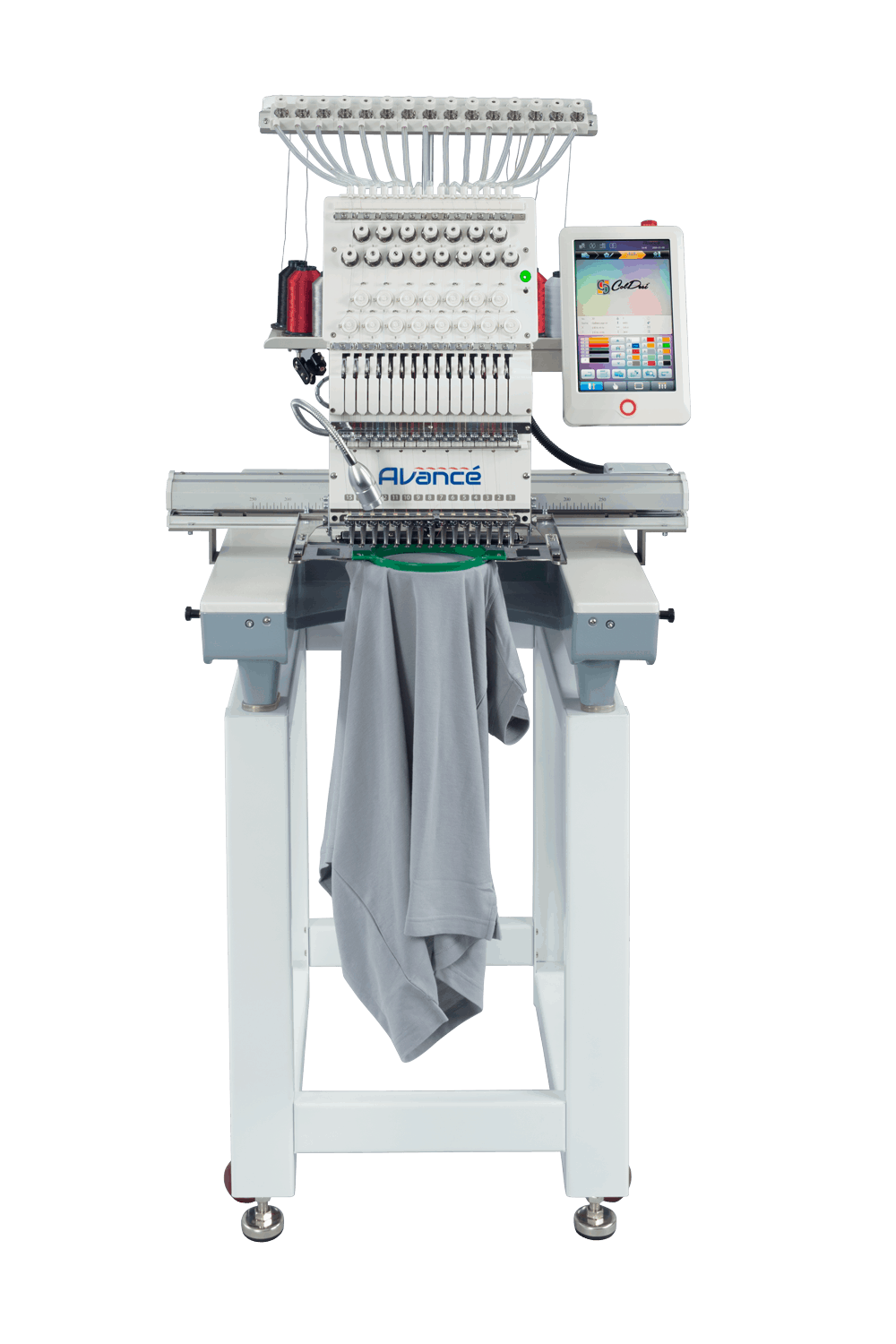

The Avancé 1501C is a 15 needle SINGLE head embroidery machine, but one with some multi-head advantages.

You can cluster 2, 3, 6 + units and turn them into an incredibly versatile multi-head embroidery system. Giving you the ability to handle large and small orders.

And the key to TODAY’s Embroidery Business success? FLEXIBILITY!

Combining single heads in a modular multi-head system maximizes your production without much of the typical downtime experienced with traditional multi-head machines.

With an Avancé 1501C modular system, you can use your machines to create the ultimate modular production system with the least amount of space.

15 Needles/Colors

1 of 8Use multiple Avancé machines to run the same job or different jobs to all machines

2 of 8Make use of small office, Avancé can easily fit in home spare room

3 of 8Embroidery Area – 22 x 14 inches

4 of 8Run multiple types of jobs at the same time

5 of 8Top stitching speeds: 1,200 stitches per minute* per head vs. 1,000 stitches per minute per head on a conventional multi-head

6 of 8A thread break on ONE head of a multi-head system stops the entire machine. On the Avancé system you simply fix the ONE thread break while the rest keep producing!

7 of 8When a traditional multi-head machine breaks down your whole business shuts down until a repair can be made or a part replaced. A modular system with Avancé keeps you making money while repairs are made.

8 of 8This is ideal for a slow-growth model for your business. You can start with one or 2, then grow your modular system as your business grows.

You will also be able to make smart use of limited space. Many multi-head embroidery machines will not fit in a home-based business – you can’t get a 4 head machine in your back bedroom – but you CAN put one or 2 single head machines in different rooms and send them designs over a network cable.

So no need for a warehouse or big commercial space.

Unlike conventional multi-head embroidery machines, the Avancé 1501C modular embroidery system allows for caps, bags, shirts, and jackets to be done at the same time

On-the-Job Advantages of Multiple Single Head Machines

There are some technical and time saving advantages of the multiple single heads approach too.

We’ve already talked about flexibility vs a traditional multi-head, but it’s worth repeating:

A traditional multi-head is only good for producing large quantities of the same thing, at multiples of FOUR.

So if you get an order for 15 hats and polos and you have a 12 head embroidery machine, you would run 12 hats, then turn off 9 heads to run the last 3 hats.

Then you would do the same with the shirts!

With multiple single head machines you would simply run what you needed to without wasting time and production capacity.

Did you realize that single head machines are actually FASTER than traditional multi-heads?

• Top stitching speeds: 1,200 stitches per minute* per head vs. 1,000 stitches per minute per head on a conventional multi-head

• Average stitching speeds: 950 stitch per minute average vs. 600-700 stitch per minute average on a conventional multi-head

Difference: Produce about one-third more with single-heads that an equivalent conventional multi-head machine because of time savings

Thread breaks should really be in both Production Time and the Maintenance sections because it certainly effects overall time to complete a job!

A thread break on ONE head of a multi-head system stops the entire machine. So that’s 4- 24 heads not working until one thread break is fixed. With a Modular system you simply fix the ONE thread break while the rest keep producing!

Machine Failure – when you’re entire business runs on one machine you are totally at the mercy of that one mechanical device. Even a high quality brand like Avancé can suffer damage from power surges, operator error or some event that might cause a head to go down. It that happens on a traditional multi-head machine you are effectively CLOSED until a repair can be made or a part replaced. A modular system keeps you making money while repairs are made.

ColDesi has many customers that are perfectly happy with a small, back bedroom style business.

More of them end up GROWING their business by offering their customers different things. So we help them get set up with a Heat Transfer Vinyl system, a Spangle Machine for Bling, or a custom t-shirt printer.

But some them grow their embroidery business to something BIGGER. They generate more and larger embroidery orders, so they need to expand their embroidery capabilities.

The downside of a traditional multi-head machine is there’s no room for slow growth.

Budget: You have to make your decision to expand all at once. Have a 12 head and need to expand -that next 12 head will cost you another $60,000. If you have a modular single head system your business can grow ONE HEAD AT A TIME. You can grow in stages. You can grow as you can afford to grow.

Space: Have enough space for your 12 head machine but need to add another? You can’t get around the cavernous space you need to house a traditional multi-head machine. BUT, you can add ad more single head machines -put them in 4 corners of a 10×10 room – can’t do that with a 4 head! Need to add 6 more machines? Just put them down the hall.

Ramp Up: The bigger a traditional multi-head machine is, the longer it will take to ship it to you. The less likely your vendor will have it in stock. The longer you have to wait for a technician to travel to you to set up the machine and test it on-site. With a Modular System – those single heads come to you fast and ready to go.

Today’s Apparel Decorator

The embroiderer of today is much more a part of the apparel decorating community than ever before. Your best chance for long term success is to be flexible, be ready for what’s next in custom tees, gifts an promotional products.

And that leads to the Avancé 1501C and a Modular Multihead system.