2022 Updated: We review methods of how to determine embroidery prices and embroidery cost… by the job, per Item, and per stitch

Not Knowing How to Price Embroidery or Monogramming Creates Fears.

There are a few factors to consider when pricing embroidery or monogramming services. You’ll need to consider more than the cost of materials. The type of thread, fabric, and stabilizer all play a role in the overall cost of the project. In addition, consider the time it will take to complete the project.

More complex designs will take longer to stitch out, and thus will be more expensive. Finally, factor in the cost of any additional services that may be required, such as digitizing or setting up a design for embroidery.

By taking all of these factors into account, you can arrive at a fair price for your embroidery or monogramming services.

Learning how to price embroidery work can sometimes seem complicated. Some business owners have expressed fears regarding embroidery prices, embroidery costs, or monogramming costs.

So, let’s take a look at some of those fears and how to get past them.

Fears: If My Price is Too High

- I won’t get enough business to pay my bills each month

- I only get one chance at embroidery prices or they will buy elsewhere

- My competitors will take my jobs if I don’t learn how to price embroidery work

- I will take advantage of people if my price is too high

- People will think I am too proud

- I will regret it if I charge too much

Fears: If My Price is Too Low

- I won’t make enough to pay my bills each month

- I only get one chance at pricing per stitch correctly

- People will take advantage of me if my embroidery prices are too low

- People will think I do cheap work if I don’t know how to price embroidery

- I will regret I didn’t ask for more

Can you Notice all the pressure people put on themselves about pricing?

Notice how the fears and potential regrets are nearly the same in each list?

Unfortunately, deciding how to price embroidery monogramming work on a commercial machine can often become a huge procrastination point.

But it doesn’t need to be that way.

Understanding embroidery prices or monogramming with well-founded pricing models

Knowing your goals up front will help remove the fears and keep your business moving forward.

To start with, it’s important to keep pricing in perspective. Learning how to price embroidery and monogramming jobs correctly is only one part of reaching your overall goals.

Pricing is not the thing that will make or break your business.

Pricing in the embroidery and monogramming machine business is a powerful tool that you can use to help yourself reach your goals. It might take time before pricing becomes second nature. But it’s well worth learning how because when done right this will be an important part of getting ahead at work or fulfilling personal obligations like family caregiving activities for example!

Your potential in the embroidery business is only limited by your imagination, so let go of any fears you have about pricing and focus on your goals instead.

Start with your Goals in mind.

Starting a business is tough and there are so many things you need to do before, during and after opening your doors. One of the most important moments in any new embroidery company’s life cycle happens when they decide what his or her goals should be as it will help them reach those larger aspirations with less difficulty!

One way that I have found success for my own small businesses was by breaking down each step into smaller milestones which made sure we were taking action towards our goal every day instead waiting until everything came together at once right off-the bat like magic (which doesn’t happen). This allowed us time along both journeys: 1) To see progress 2 )Feel confident about wherewe

Let the accomplishment of those smaller goals add up to your bigger goals.

For instance, let’s say your big goal is to hit your break-even point in your business (the point where sales cover all expenses) within the first year.

Rather than focusing on a large yearly sales goal, instead chose 4 or 5 actions you can do each day, week, or month.

Let’s say your goal was to learn how to price embroidery for the custom shoe making market? Having that goal in mind would be critical.

Here’s an Example: Embroidery Prices with Your Goals in Mind:

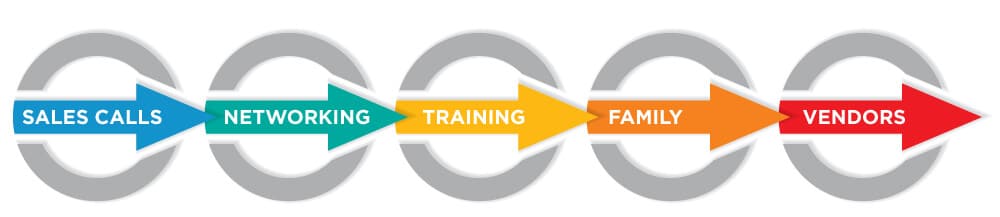

- Make 10 outbound sales calls each day

- Attend 2 business networking functions a month

- Spend 1 hour a day for the first 2 months in training and learning

- Take time for family each week, stop to ask how they are holding up

- Explore 3 potential new vendors each week, etc

- Spend an hour each month learning how to price embroidery or monogramming work.

If by chance you have an existing business and have never taken the time to write down your goals, now is a perfect time to get started.

Anyone who is searching for the best way to price embroidery or monogramming has a great opportunity to start making written goals.

These goals will inform your pricing decisions and help you decide which pricing models to use which support your overall goals.

Cost, Retail or Wholesale Strategies

Understanding pricing on a more general level is important before we can discuss pricing models.

There are three broad categories for pricing that need to be understood in order to speak the same pricing language that your customers, partners, vendors, and other colleagues will speak.

The Embroidery Cost Price

Cost pricing is often the starting point of any pricing model. It’s unique for each business, and depends on many different factors that apply specifically to the individual business.

Costs are classified into two broad categories and it’s important to be able to have some understanding of the differences when learning how to price embroidery.

Fixed Costs – any costs that do not change with an increase or decrease in the amount of the goods or services provided.

These are expenses that the embroidery company has to pay regardless of if any business activity is conducted or any sale is made that month.

Typically this includes things such as rent, utilities, lease payments, monthly maintenance payments, owner’s salaries, and other fixed overhead costs.

These fixed costs get tracked to each job based on a number of jobs expected for each month.

For instance: if your fixed costs for a specific month are let’s say $1,450 (rent, lease payments, fixed supplies, etc.) and your Sales Volume is let’s say $5,000 then your fixed costs represent about 30% of your Sales Volume.

Imagine now if you are able to double your sales volume to $10,000. Now your fixed costs would now only add up to 15% of your Sales Volume. This will leave a larger percentage (85% instead of 70%) for cost of goods and Profits!

When pricing monogramming machine jobs and items, keep in mind that any increase in sales volume effectively reduces the percentage you pay in fixed costs. Higher sales volume leaves more $$$ for higher profits!

Variable Costs- Variable costs fluctuate with production volume, they typically depend upon how much you sell or prepare to sell and how many orders you receive that month.

Learning to calculate and classify the variable costs of your monogramming machine business s one of the more tedious things to get a handle on when learning how to price embroidery or a monogramming job.

However, keep the task in perspective. It is nothing more than a gathering of the costs that change with each job. For a quick rundown of the different monogramming machines out there compared to our Avancé brand, click here to learn more.

Wholesale Embroidery Prices

The Wholesale price is what commercial embroidery and monogramming machine businesses typically pay for blank garments, thread, backing, bobbins, etc.

Wholesaling is one of the steps in a typical supply chain, which includes manufacturers, distributors (blank garments) and retailers (most embroidery and monogramming machine services).

The apparel distributors typically have large warehouses locally where they store hundreds of thousands of garments which are blank and ready to be delivered to embroidery machine or monogramming machine shops in their local areas.

As a new startup or existing embroidery business owner, you can often show the wholesale company a copy of the embroidery machine invoice and be set up with a wholesale account.

Having purchased a commercial monogramming machine is a good indicator to Wholesalers that you mean business. They will give you a better sense of how to price embroidery work if you know how to ask.

Embroidery Prices & Models for Machine Embroidery Jobs

There are literally dozens of ways to go about pricing machine embroidery jobs. Pricing models help business owner’s price their embroidery work by the job, by the items, or per stitch.

However, there are a few particularly good pricing models that work best for an embroidery and monogramming business and we cover those here.

The Retail Price

Embroidery prices for retail is how most embroidery business typically gets done. The overarching category of a typical embroidery or monogramming business is called “decorated apparel”.

Business owners in the decorated apparel industry end up purchasing a monogramming machine or commercial embroidery equipment which they use to embellish custom t-shirts or polos or dress shirts, or custom embroidered hats, etc.

Retailers and other users purchase goods from wholesalers and then sell the products at a higher price to cover costs and generate profits.

They do this by learning and using multiple pricing models. These pricing models tell them how to price embroidery or monogramming work

This is a method of pricing embroidery jobs that is often used by embroidery & monogram shop owners. It is supported across the board by many of the apparel distributors in the US.

Keystone pricing is a simple and easy to use retail pricing strategy where the end price is set at double the wholesale price.

Embroidery business owners and operators are typically entitled to wholesale pricing by the companies that they get their blank garments from.

Wholesale companies are not set up to deal with retail traffic and have a business model that focuses on Retail shops like those with a commercial embroidery or monogramming machine.

These wholesale companies often print their catalogs at keystone price (twice the price you pay) so that it provides a great starting point for the embroidery company when dealing with the end buyer.

The embroidery business owner can simply look at the price in the catalog and can show the pricing to the end customer. They can know that there is already a fair profit built into the price to begin with. If new to the business, this method is a great starting point.

Many times shop owners will start with the keystone embroidery prices and add an extra fixed price to cover the cost of the specific embellishment. Other shops prefer to use a cost per thousand stitches approach.

- Polo Shirt Catalog Price =$24.50 (customer sees this price as starting point)

- Wholesale Price = $12.25 (½ catalog price – embroidery or monogramming business pays this, plus shipping)

- Retail Pricing = $29.95 (full catalog price plus a set price for embellishment -$5.45 in this case)

- Gross Profit = $29.95 – $12.25 or $17.70 per item.

- Net Profit = $17.70 per item – fixed costs % and any remaining variable costs.

Another benefit to this model is that since the entire catalog has been printed with the keystone pricing it tends to eliminate further negotiation on the part of the customer.

It’s clear to them that a great effort has been made to put the catalog together, so they figure the pricing must be accurate and non-negotiable. This works to the benefit of the embroidery business owners because they have to do little to justify their price to the end user. This all helps when trying to figure out how to price embroidery monogramming work.

However, keep in mind that this method is only a starting point. As the wholesale cost of the item increases (say Brand Name Polos and expensive Dress Shirts) then keystone and keystone plus pricing can get quite high.

Competitors will often use other pricing models to justify bidding larger jobs at lower prices so when using this method, it’s important to keep the pricing conversation open with the customer and get feedback on how you’re pricing is holding up against the competition.

Lastly, Keep in mind, you are not actually calculating your costs with this method so be willing to negotiate if one of your other embroidery cost methods or your competition indicates the price using this method is too high.

Time and materials billing has long been used in the commercial construction industry.

By definition, it represents an agreement between the customer or end-user and the company producing the product. In the apparel business, it’s typically used for larger custom jobs that are outside of the realm of what your business typically produces.

For instance, you might use a Time and Materials approach to price out 100 high-end leather jackets with multiple placements. However, Time and materials are perfectly appropriate for any job you choose.

If you don’t know your costs for a specific type of job, try a Time and Materials approach. As the shop owner, you negotiate with your customer for them to agree to pay for all the materials and cost of goods used in the making of the product. In addition, they pay for the time it takes to produce the job. This is all part of the “how to price embroidery monogramming work” process.

Sometimes there is an additional agreed upon mark-up for profit margin added in. However more often than not all the fixed costs and the profit is included in the per hour price for the work.

For instance, if your fixed costs are $1,450 per month and your shop is open for 40 hours a week. Then that works out to about 173 hours a month, and those embroidery expenses need to be divided by $8.38 per hour for fixed expenses.

Using this Time and Materials approach, you may decide that you intend to make $25 per hour for your work and another $7 per hour in profit. So the fixed costs get added to your pay plus your profits to add up to, in this case, $8.38+25+7 = $40.38 per hour. This figure then becomes the agreed per hour price for your work.

It also represents the use of your equipment and resources. The customer also agrees to pay the price for materials on top of this figure. This method ensures that you get the pay you deserve for your work. In the case of a complex or a very large job, it makes sure you get paid enough.

It also ensures you don’t pay too high a price for not estimating embroidery costs correctly. But it has drawbacks in that every hour the machines are not busy effectively reduces the amount of pay per hour. So you must balance your need to get paid what you are worth against keeping the machines busy.

If the machines aren’t busy, then you are paying for the fixed costs out of your pocket. So it’s better to keep your machines moving.

It’s possible to win the battle by having the “highest price in town” but lose the war when the bills come in at the end of the month. Making sure you have high-profit work is the way to keep your hourly rate to a maximum. But keeping your machines busy is the way to make sure you get to keep all those high profits you earn on the jobs you do.

Cost-plus pricing is a more complex strategy in which the selling price is determined by adding a specific profit margin or mark-up on top of the unit costs of the goods sold.

This is typically calculated on a per-job basis, and it’s important to add in the fixed costs and the variable costs. Cost breakdowns must be deliberately kept and comparisons made at regular intervals. This method is tough for a start-up business because there is little data to base your embroidery prices.

Every business has a different set of costs, and those costs get lower and lower as a business grows. It is only after you have produced many jobs that you begin to get a good feel for the final costs for a specific niche of your business. Over time, you learn how to price embroidery monogramming better as you go along.

This pricing model is excellent however for any business that has been in business for a year or more. It’s important to go back and spot check the costs of former jobs.

Doing a post-mortem analysis on larger jobs or specific jobs, you believe to be the most profitable is important. Spot checking your jobs allows you to compare the profits earned for each specific job type. The goal is to keep doing more jobs that you enjoy and make the most profits.

Compare this method to your other embroidery prices and make sure your pricing supports your daily, weekly and monthly goals. For instance, let’s say your machines are so busy each month that you don’t have time to make it to business meetings.

Or perhaps you can no longer pick up your kids from school because you are too busy. It may be time to raise your embroidery prices so that you can work fewer hours but still make the same amount each month. In general, you want to raise your prices every year anyway.

The more your customers learn to trust the quality of your work and service, then the more you can charge and still expect those customers to remain loyal. Customers will respect that you know how to price embroidery work properly.

It’s always recommended to know your costs and make a serious effort to add up all the costs that go into the work you are getting paid to do.

However, in the beginning, as mentioned above, it can be a daunting task, and this can often be a sticking point. So another method that works very well is pricing to the market. There are all sorts of complicated ways to gather data, and one can spend as much time as they want to examine every possible market influence on their local embroidery or monogramming business

The people who will be paying for your work are often already educated about what they are willing to pay for embroidery prices.

Pricing to market is simply a process of asking around and shopping, monogramming machine competitors in your local area, and asking your potential customers the going rates for various jobs.

The thinking is that if successful, the other businesses in your area are already charging a price that sustains their businesses. Using this method, it is assumed those embroidery prices will also sustain your business.

Regarding how to price embroidery monogramming: it is sometimes an uphill battle to get an existing market to agree to pay a higher price for items or jobs they have bought for many years. So when in doubt, there is nothing wrong with using the going rates for work in your area as a starting point. However, keep your eyes open for an opportunity to add value to your monogramming machine business as you go along.

It’s important that you only compare prices with other companies in your area that offer the same level of service and product as you do.

For instance, if you consistently provide a more expensive type of t-shirt than the normal for your area, then it will be important to make sure that your price according to the extra value that you bring to the local market.

It has long been a standard in the embroidery industry to price jobs on a per thousand stitches basis.

There is an enormous amount of pressure and opinions that develop concerning the “right” price per thousand is. Industry software has even been designed to help out which will calculate literally every single meter of thread that goes into a specific job.

The theories and calculations and arguments can get quite intense. How much-fixed costs go into each stitch anyway? Are all stitches considered equal? Does each machine produce the same results?

What if I have a 4-head or a 6-head machine when another business only has a 1-head? Should I then charge less? On and on… To begin with, it is very hard, if not impossible, for even industry experts to be able to guess upfront from a picture how many thousand stitches a particular design will end up with.

It’s not unusual to be off by 15 to 20% or more from the actual count when the job is finished. Also some jobs cause more problems than others.

Sometimes a design that looks so simple to the customer can represent a very large amount of time spent on an embroidery machine. Sometimes a design can have a low stitch count, but be on a particular material to make it break thread 4 or 5 times more often. All of which are hard to judge upfront.

So it can leave your customer feeling like their price is always a moving target. The important point is that the “per thousand stitches” method is essentially a “Time and Materials” method.

It is an attempt to break down the overall fixed costs and variable costs and reduce them all down to an amount you intend to get paid for every thousand stitches your machine produces. The bottom line is to keep this method in perspective of your other methods and use it to compare one model to another.

You may find that this method is most reliable for certain jobs (Typical polo left chest logos, etc.) but be very lacking in other jobs. That’s why it’s important to keep your pricing flexible.

Be Flexible as you Price Embroidery Work and Services for Customers

Lastly, keep pricing in perspective and make sure your embroidery costs & monogramming machine methods are working for you. Not the other way around.

Your job costing, pricing, and business methods should align with your personal goals. How you set your embroidery prices & costs of work should reflect your personal goals.

Pricing embroidery work and monogramming machine services for customers gets easier with time, so keep at it and call ColDesi, Inc. if you have specific questions about pricing. Our apparel industry experts will be happy to help.